SPECIAL TOOL

REGARDING OUR SPECIAL TOOLS

CJV's strengths lay in its ability to provide special tools—the optimal tool shape which fully considers customer productivity is directly designed by our technically-capable sales staff, and the final product is delivered to customers—all while fulfilling fast deliveries to customers which leave a lasting impression, and strictly adhering to set delivery term. From reduced processing times and extended tool life, to aspects concerning precision, and burr, etc., customer's concerns are swiftly handled.

Four Reasons Why CJV is Chosen by Customers

-

-

POINT01

-

SHORTER DELIVERY TERMINVENTORY COST REDUCTIONS

With shorter delivery term achieved through our unique production system, and technically-capable sales staff directly handling enquiries, design, and delivery, the time it takes to reach the manufacturing phase is also vastly reduced.

-

-

-

POINT02

-

STRICT ADHERENCE TO DELIVERY TERMMANAGEMENT COST REDUCTIONS

Through our decentralized production system with production bases both in Japan and overseas, and our thorough scheduling management which employs a uniquely designed delivery management system, our customers' desired delivery dates are strictly upheld.

-

-

-

POINT03

-

STABLE SUPPLYSTABLE PRODUCTION

With our original production management system that has been built through numerous commissioned projects, shorter delivery term and a strict adherence to delivery dates have been made possible, and we can provide a wide range of cutting tools.

-

-

-

POINT04

-

HIGH PERFORMANCEIMPROVED PRODUCTIVITY

Our engineering sales staff members who possess know-how that has been uniquely cultivated in our company can design optimal, high-quality tools that correspond with customer needs.

-

PRODUCTS

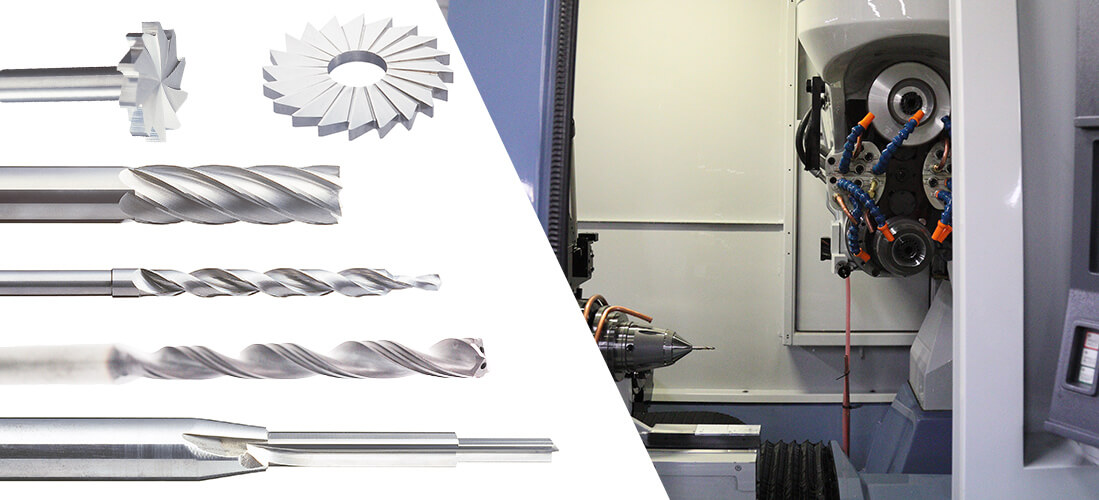

SOLID SPECIAL CUTTING TOOLS MADE FROM CARBIDE AND HIGH-SPEED STEEL

Our global system provides 100% satisfaction

The system we have laid out has enabled us to not just propose workpiece plans to customers, but also to deliver them in as short as three days—even for designs that start from scratch. These services for short delivery term are available country-wide, no matter the customer's location.

PCD AND CBN SPECIAL CUTTING TOOLS

Diamond tools that improve processing accuracy and reduce costs

Using the optimal PCD tools for machining non-ferrous metals such as aluminum and resins such as Teflon and acrylic, we improve productivity by means of stability in precision, and by extending the cutting tools' life.

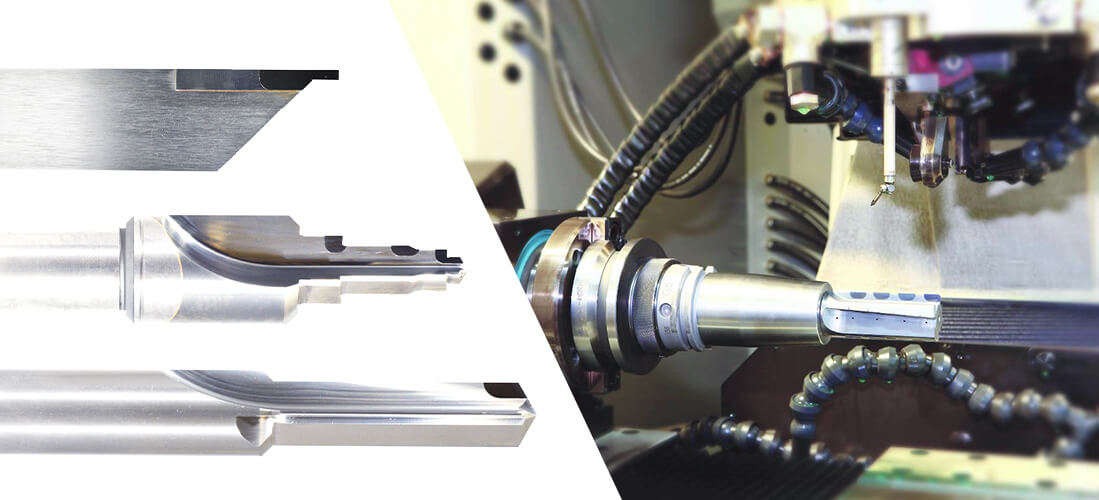

BRAZED SPECIAL CUTTING TOOLS

By making base and shank part with steel materials, we reduce the weight of tools and save on costs

Our brazing methods comprise of forward-facing brazing (V brazing / cone brazing / faucet brazing) board-chip brazing, composite brazing, and sandwich brazing. We can flexibly handle design and production requirements which correspond with diverse applications.

SPINDLE-INTEGRATED SPECIAL CUTTING TOOLS

We have realized high rigidity and high precision through integrated production of holders and tools

We offer design and production services that meet the appropriate use, with compatibility of BT30/40/50, and HSK 40/50/63/100, and can fine-tune tip mounted products and those that have strict diameter tolerances using adjustable tools (cartridge / microbore.)

MICRO DRILL

Please give the staggering value-packed CJV micro drill a try.

This is a low-priced, ultrafine particle carbide and strong-twisting drill. It has a small diameter, and is available in a range of 0.1 to 3.15, with increments of 0.05.

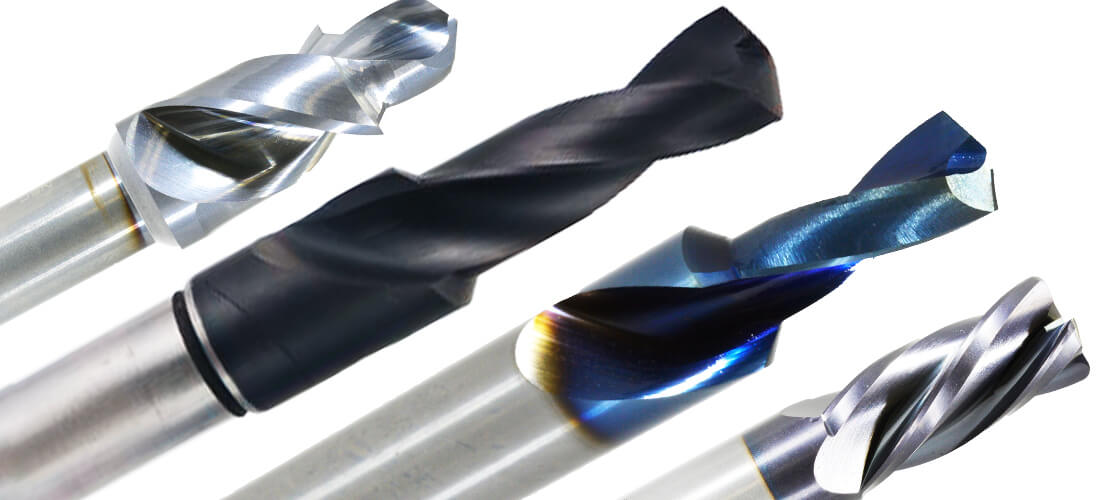

VARIOUS COATINGS

Extended cutting tools life and reduced costs have been realized through our coatings' improved hardness, improved wear resistance, and improved heat resistance, etc.

With various coatings such as TiN, TiCN, TiAlN, AlCrN, DLC, DIA, etc. the appropriate coating is selected depending on the customer's needs, including the workpiece material, accuracy, cost, etc.

ABOUT OUR COMPANY'S OTHER LINES OF BUSINESS

Providing High Quality, Low Cost Inspection Tools and Jigs That Fit All Sorts of Demands

Starting with our collet chuck and guide bush for automatic lathes, along with numerous carbide/gauge steel measuring tools and test jigs, and other work jigs, etc., our products improve the efficiency and accuracy of people's work—this stems from our extensive proposal performance that is based on actual past results.

We Offer Next-Generation Washing Machines That Both Reduce Environmental Burdens, and Include High-Performance Technology

Our next-generation aqua-based ultrasonic cleaning system, which goes hand in hand with peace of mind, safety, and ease, uses "water", not organic solvents and hydrocarbons. Reliable cleaning quality, space saving for cleaning processes, and a minimization of cavitation noises—together with precision cleaning that is gentle to the environment—will all be made possible.

Proposing Optimal Manufacturing Environments That Use Machining Tools and Specialized Machines

Whether located in Japan or overseas, or from manufacturers' general-purpose machines to the specialized ones—we meet the numerous needs of customers, including requirements, prices, performance, and appointed day of delivery, etc. We, as a cutting tool manufacturer with thorough knowledge of machining, take responsibility in selecting machine types, and make significant contributions for productivity improvements regarding mass-produced goods.

We can respond to

any enquiries relating to cutting process.

※If you cannot send for any reason, please contact info@cjv.co.jp